Introduction

A food safety training needs assessment helps you find the real skill gaps that cause safety failures. It saves time, money, and effort. It also helps SMEs and programs train the right people on the right tasks. Most training fails because it guesses. A TNA removes guessing.

This training needs assessment supports a wider approach to stronger systems and skills. See capacity development in Africa for safer food systems.

Food safety capacity building works best when you fix both skills and systems. So, this guide uses simple steps. It also gives you a clear way to spot non-training issues. For example, missing tools or unclear SOPs.

In this post, you will learn how to set the scope, pick target groups, and define competencies. Then you can build a food safety training plan that fits your reality.

Step 1: Define the goal and scope of the food safety training needs assessment

Start with a clear goal. Keep it short. One sentence works.

Step 1.1: Set the goal (SME and program examples)

Pick one main goal. Then add one supporting goal.

SME examples

- Reduce repeat inspection findings in 60 days.

- cut customer complaints linked to hygiene.

- Improve temperature control and recordkeeping.

Donor or government program examples

- Improve compliance across target SMEs.

- Strengthen risk control in priority value chains.

- Support a shift to risk-based inspection.

Next, write what success looks like. Use simple metrics. For example, fewer repeat nonconformities.

Step 1.2: Set the scope (what you include)

Define scope in four lines:

- Sites (one facility or many).

- Roles (handlers, supervisors, QA, inspectors).

- Processes (receiving, storage, cooking, cooling, cleaning).

- Timeline (7, 14, or 30 days).

This step protects your time. It also keeps the assessment realistic.

Step 1.3: Decide the timeline (fast options)

Use one of these timelines.

7-day TNA (SME fast track)

- 1 walkthrough

- 5 short interviews

- Review key records

14-day TNA (multi-site SME or small program)

- 2 walkthroughs per site

- More roles covered

- Simple scoring and plan

30-day TNA (program baseline)

- Multi-site coverage

- Standard tools

- Baseline metrics and reporting

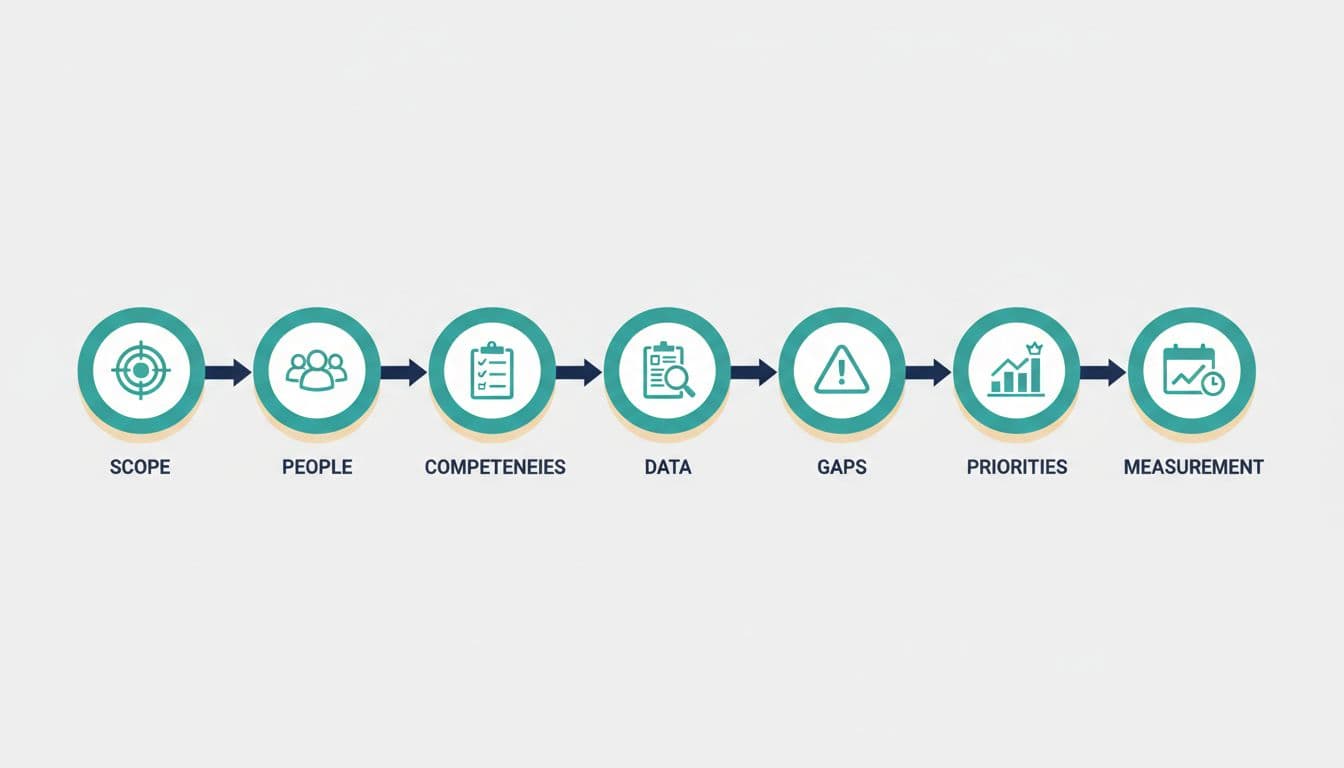

This simple flow shows how a training needs assessment moves from scope to measurement.

Step 2: Identify target groups and stakeholders

A training needs assessment for food safety works best when you involve the right people. Do not depend on managers alone. Also include frontline staff.

Step 2.1: List roles for the training needs assessment (SME checklist)

Start with the roles that touch food daily:

- Food handlers and cooks

- Cleaners and sanitation staff

- Receiving and store staff

- Supervisors or shift leads

- Owners or managers

Include maintenance staff when equipment fails often. If you manage delivery, include drivers too.

Step 2.2: Add stakeholders (program checklist)

If you run a program, include:

- Local inspectors and supervisors

- Lab partners (public or private)

- Industry groups or SME associations

- Training providers

- Local authorities (as needed)

This step improves buy-in. It also reduces conflict later.

Step 2.3: Assign simple responsibilities (who does what)

Assign four roles. Keep it simple.

- Lead: runs the process and sets deadlines.

- Contributors: provide data and join interviews.

- Approver: confirms priorities and budget.

- Trainer or coach: delivers training and follow-up.

Clear roles speed up action. They also reduce delays.

Step 3: Define required competencies (what “good” looks like)

You cannot find gaps without a clear standard. So, define competencies by role. Keep them tied to daily tasks.

Step 3.1: Food safety training competencies to include in a training needs assessment

Use these areas as your base:

- Hygiene and sanitation (GHP)

- Process controls (time, temperature, cross-contamination)

- HACCP basics (hazards, CCPs, corrective actions)

- Records and verification (logs, checks, internal reviews)

These areas support a strong food safety competency framework. They also guide your training plan. If you need a practical example to train teams, see my HACCP plan for restaurants.

Codex sets a practical global baseline for hygiene and HACCP, so it helps you define what “good” looks like during a training needs assessment. See the Codex General Principles of Food Hygiene (CXC 1-1969) and HACCP annex.

Step 3.2: Write competencies as task statements

Avoid vague topics. Use action statements.

Examples:

- Wash hands using the correct steps and timing.

- Check delivery temperatures and reject unsafe loads.

- Separate raw and ready-to-eat foods at all times.

- Record CCP checks and act on failures.

Each statement supports later evaluation. It also supports coaching.

Step 3.3: Set three skill levels (basic, working, strong)

Define levels for each role. This helps you tailor training.

- Basic: a new worker follows the steps with help.

- Working: a worker follows the steps without reminders.

- Strong: a supervisor checks others and fixes problems.

This approach makes food safety training evaluation easier. It also supports fair supervision.

Step 3.4: Map competencies to risk in training needs assessment (focus on what matters)

Now connect tasks to risk. Ask one question. What failure here can cause illness or a shutdown?

Prioritize those tasks first. Then build the rest later.

Step 4: Collect data for the food safety training needs assessment (use 3 sources)

Use records review, on-site observation, and short staff interviews so you compare what paperwork shows, what people do in real time, and what teams say blocks good practice. This keeps your results honest. It also reduces bias.

Step 4.1: Records to review during a food safety training needs assessment

Start with records you already have. They show patterns.

Check:

- Inspection reports and corrective actions

- Internal audit notes (if you have them)

- Temperature logs (cooking, cooling, storage)

- Cleaning schedules and verification checks

- Customer complaints and returns

- Training attendance lists (who trained, when, on what)

Then note repeat failures. Also note missing records. Those often signal a system gap.

Step 4.2: Observe work on-site (see the real workflow)

Next, do a short walkthrough. Keep it calm and respectful. Tell staff you look for process issues, not blame.

Watch:

- Handwashing and glove use

- Raw and ready-to-eat separation

- Thermometer use and storage temps

- Cleaning method (tools, dilution, contact time)

- Waste flow and pest risks

- Labeling and date marking

Also take simple notes. For example: “No sanitizer test strips.” That supports action later.

Step 4.3: Run short interviews (10–15 minutes each)

Then ask focused questions. Use the same questions each time. This improves comparisons.

Ask managers:

- What issues repeat during inspections?

- Where do errors happen most often?

- What blocks staff from doing it right?

Ask staff:

- Which task feels hardest?

- What do you do when a check fails?

- Which SOP feels unclear?

Finally, confirm gaps with examples. That improves accuracy.

Step 4.4: Optional quick survey or mini-quiz in training needs assessment (keep it short)

Use this only if it adds value. Keep it simple.

Try:

- 5-question quiz on temperature control and cross-contamination

- 10-item self-check list staff can complete in two minutes

However, do not rely on surveys alone. Observation matters more.

Step 5: Identify food safety training gaps in a training needs assessment

Now convert notes into clear gap statements. This step drives your food safety training plan.

Step 5.1: Write each gap in one sentence

Use this format:

Role + task + expected standard + current practice + risk

Example: Kitchen staff must log cooking temperatures for chicken, but logs stay blank on busy shifts, so undercooking risk increases.

Keep gaps factual. Avoid blame words. Focus on behavior and results.

Step 5.2: Sort root causes into 5 categories

Use these root causes. They keep decisions clear.

- Knowledge gap: staff do not know the rule.

- Skill gap: staff know it but cannot do it well.

- Behavior gap: staff can do it but skip it.

- System gap: SOPs, tools, or workflow block success.

- Management gap: no checks, no feedback, no follow-up.

This step prevents the “train everything” mistake. It also protects your budget.

Step 5.3: Decide training fix vs system fix

Use a quick rule.

Use training and coaching when knowledge or skill is missing. Fix tools and workflow first when the system blocks good practice. When habits slip, add supervision and simple reminders.

Often, you need both. So, pair a short training with one system change.

Step 6: Prioritize needs (simple scoring that works for SMEs and programs)

A training needs assessment for food safety must end with priorities. Otherwise, nothing changes.

Step 6.1: How to prioritize training needs assessment findings (simple scoring)

Score each gap using three factors:

- Risk: Can this cause illness or shutdown? (High/Med/Low)

- Frequency: How often does it happen? (Daily/Weekly/Rare)

- Feasibility: Can you fix it soon? (Easy/Medium/Hard)

Then focus on High risk and frequent gaps first. Food safety gaps carry real health and economic costs. The WHO food safety fact sheet gives a clear global view of the risk.

Step 6.2: Build a Top 5 list (keep it actionable)

SMEs should pick the top 3 to 5 gaps. This keeps training realistic.

Program teams can go broader. Group priorities by role and by sector:

- Top gaps by role (handlers, supervisors, inspectors)

- Top gaps by sector (meat, dairy, ready-to-eat)

This structure keeps results useful for planning and reporting.

Step 6.3: Match each priority to the right training method

Choose the delivery method that fits the problem.

On-the-job coaching works best for habits. Short toolbox talks help with reminders. Classroom sessions fit supervisors and team leads. Job aids support daily steps (posters, checklists). This improves food safety training evaluation later. It also improves follow-through.

Some hazards need extra focus. If you work with maize or groundnuts, aflatoxins often drive high-risk training priorities. The WHO fact sheet on mycotoxins (aflatoxins) gives a clear overview.

Step 7: Build a food safety training plan from your training needs assessment

Now turn priorities into a plan people can run.

Step 7.1: Write clear learning outcomes (simple and measurable)

Write outcomes as actions.

Good outcome examples:

- Kitchen teams record cold storage temperatures twice daily.

- Team members mix sanitizer at the right strength and check it.

- Supervisors verify logs and act on failures the same day.

Avoid vague outcomes like “understand hygiene.” Action wins. If you want a formal system view that connects training, documentation, and verification, review the ISO 22000 food safety management system standard.

Step 7.2: Add prerequisites so training sticks

Training fails when basics stay missing. So, list prerequisites.

Common prerequisites:

- Thermometers that work

- Simple SOPs (one page)

- Time on shift for checks

- A supervisor sign-off routine

Then assign an owner for each prerequisite. This speeds progress.

Step 7.3: Build a schedule that fits operations

Keep sessions short. Protect production time.

For SMEs:

- 15–30 minutes per session

- Repeat across shifts

- Add onboarding for new staff

For programs:

- Combine short sessions with field coaching

- Avoid “one workshop and done”

This approach supports capacity building for food safety, not just attendance.

Step 8: Measure results in food safety training need assessment (simple indicators that show progress)

You need proof that training works. You also need data to improve.

Step 8.1: Use 3 levels of measurement

Use these three levels. They fit both SMEs and donors.

- Knowledge: quick checks, short quizzes

- Behavior: observation and supervisor sign-off

- Results: fewer findings, better logs, fewer complaints

This structure strengthens your reporting. It also supports future funding.

Step 8.2: Pick 5 metrics that you can track

Choose metrics you can collect without stress.

Good metrics:

- Temperature logs completed each week (percent).

- Sanitation checks passed (percent).

- Repeat inspection findings (count).

- Corrective actions closed on time (count).

- New staff trained within 30 days (percent or count).

Keep metrics simple. Review them often.

Step 8.3: Set a review routine

Set a cadence and stick to it.

- SMEs: weekly review for 4 weeks, then monthly

- Programs: monthly review, plus a quarterly summary

Then adjust training based on evidence. That keeps your plan alive

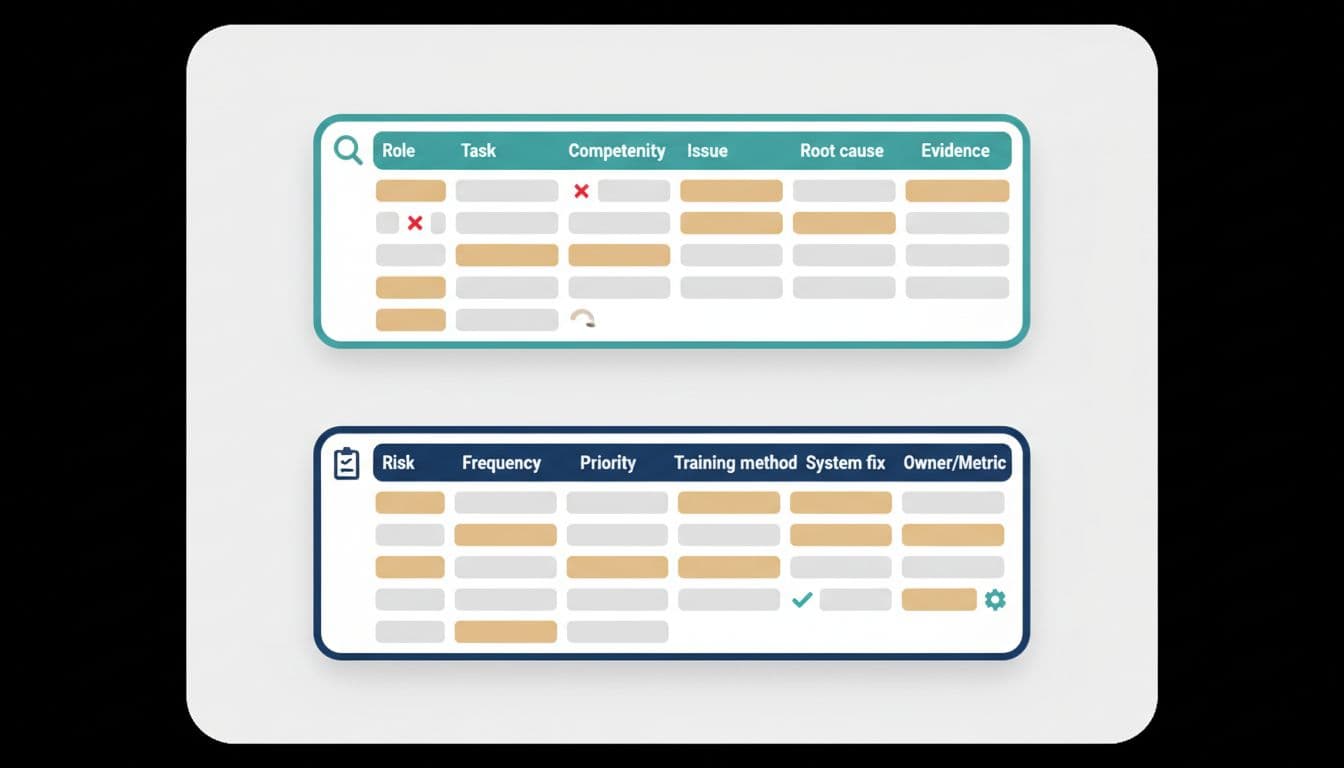

Simple Food Safety Training Needs Assessment Template (copyable table)

Copy these two tables into a document or spreadsheet. Then fill them during your walkthroughs and interviews. Use Table 1 to capture the gaps you see. Next, use Table 2 to turn those gaps into a simple action plan.

Table 1: “Find the gap” (diagnosis)

Root cause category* | Evidence source** | ||||

|---|---|---|---|---|---|

Kitchen staff | Cooking poultry | Time and temperature control | No temperature logs on busy shifts | Behavior + management | Observation + records |

* knowledge/skill/behavior/system/management/etc. | ** record/observation/interview/etc.

Table 2: “Fix the gap” (action plan)

Risk (H/M/L) | Frequency | Priority (1–5) | Training method | Non-Training Fix (If needed) | Owner + metric |

|---|---|---|---|---|---|

H | Daily | 1 | 20-min coaching + shift reminders | Add log sheet at station | Supervisor; % logs complete |

How to use the training needs assessment template (in 15 minutes)

- Fill “Role” and “Critical task” first.

- Then write “Current issue observed” using facts.

- Finally, score risk and frequency. Then assign priority.

Common mistakes (and quick fixes)

Mistake 1: You train everyone the same

Fix: define role-based competencies. Then focus on job tasks.

Mistake 2: You only use surveys

Fix: add observation plus record review. These show the truth.

Mistake 3: You create a plan that is too big

Fix: choose a Top 5 list. Then run short sessions weekly.

Mistake 4: You skip follow-up

Fix: track 3–5 metrics. Also add supervisor checks.

Mistake 5: You blame staff for system failures

Fix: fix tools, SOPs, and workflow first. Then train and coach.

Next steps (do this this week)

If you run an SME

- Do one walkthrough this week.

- Review your last inspection report.

- Fill the template for your top 10 tasks.

- Pick your top 3 gaps.

- Start one short coaching session per week.

If you run a donor or government program

- Use one standard template across all sites.

- Align priorities with inspection risks.

- Budget for coaching and follow-up, not workshops only.

- Track the same metrics across sites.

Finally, connect this TNA to the bigger system. Read capacity development in Africa for safer food systems and use it as your main guide for long-term improvement.